Overview

With Q-Chess Mobile, you can quickly and easily capture relevant operational data with the mobile app and use the captured data to control production and/or evaluate it later to optimize production processes.

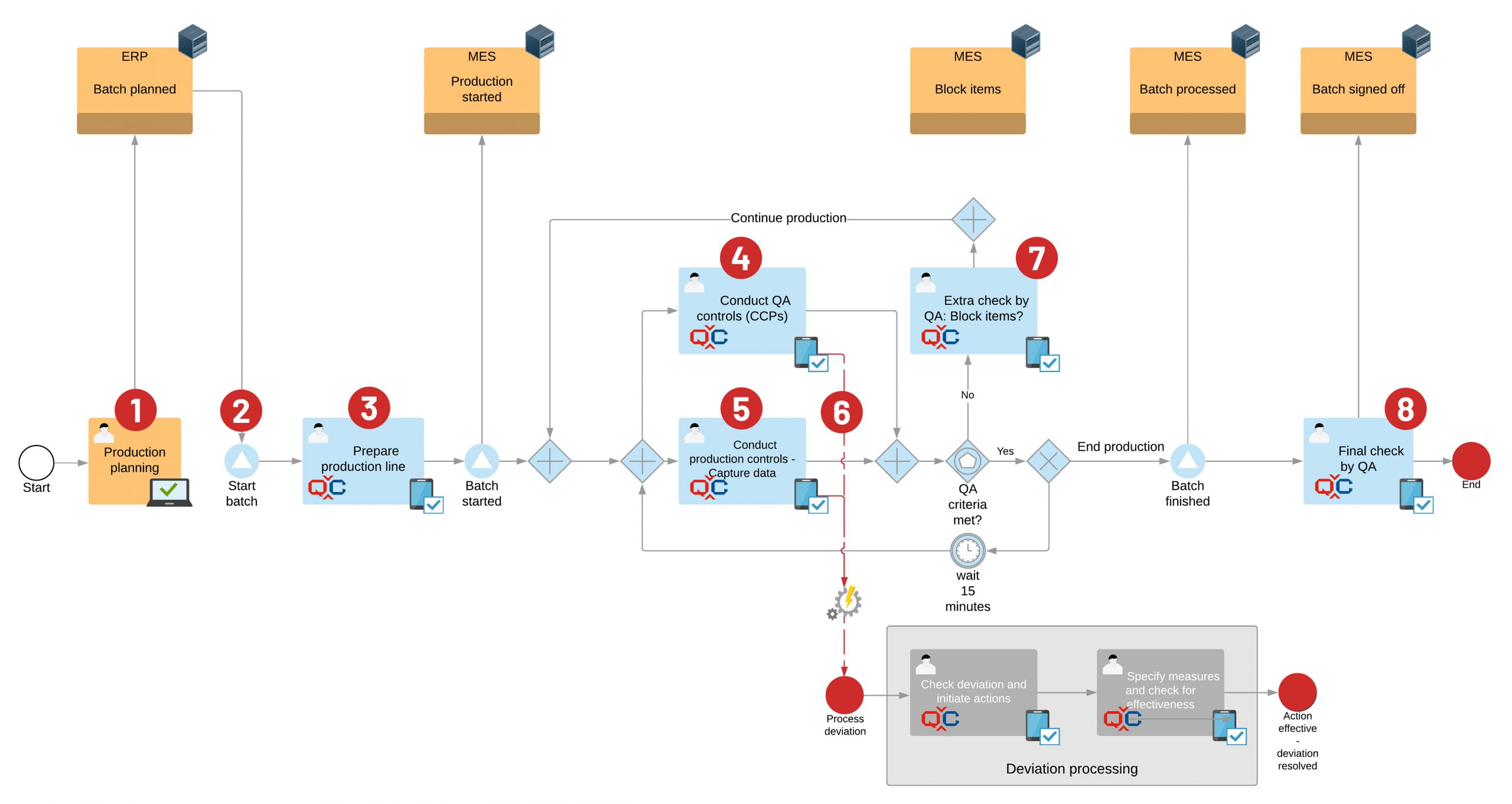

Bridging the gap

Q-Chess Mobile can exchange data with existing IT systems (such as ERP, MES or LIMS) via any interfaces, so that an integrated quality management process can be mapped on the basis of Q-Chess Mobile workflows.

The data collected via the Q-Chess Mobile App can be used to:

- Block/release batches.

- transfer postings (e.g. from warehouse A to warehouse B)

- to request further inspections by the QM management if, for example. Quality characteristics were not 100% complied with or automatically generate deviations.

This makes Q-Chess Mobile the “link” between production and quality management and enables seamless data exchange between the IT systems involved.

Management Dashboard

With the Q-Chess Management Dashboard, production-critical data is immediately available for evaluation and it is ensured that the acting persons are always informed about the current status of the ongoing production.

Practical example

Monitoring and controlling production based on critical production and quality parameters is a critical success factor. The higher the degree of automation, the faster the reaction to deviations. This saves time and resources and increases product quality.

Plan production

In the ERP system, it is planned per line which production orders will be executed on a line.

Start production

The production control system (MES system) triggers the start of production. In Q-Chess Mobile, the workflow for controlling the production checks as well as the quality checks is started. The workflow begins with production preparation.

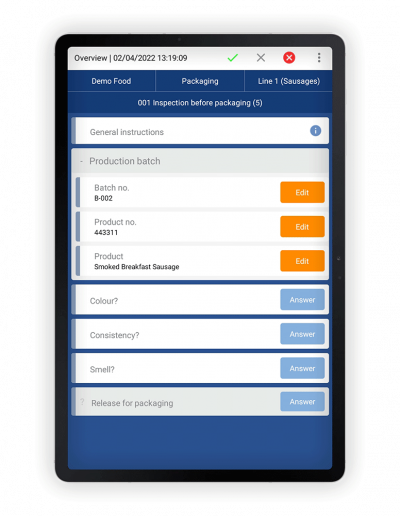

Prepare production

At the production line, the mobile device shows which production-preparation measures have to be conductes to start up the line. On the mobile device, the machine operator must confirm that the necessary steps have been carried out:

- Cleaning

- Testing of scales and thermometers

- Setting of machine parameters

- Checking all required ingredients

- etc.

When the confirmation is done in Q-Chess Mobile, then Q-Chess Mobile reports back to the MES system that the production can be started.

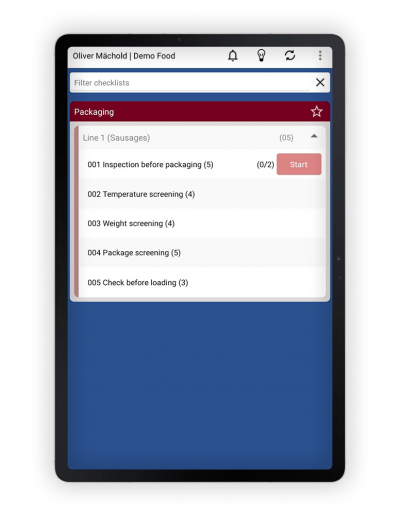

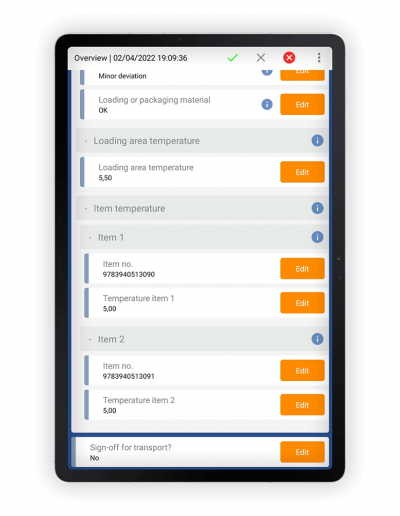

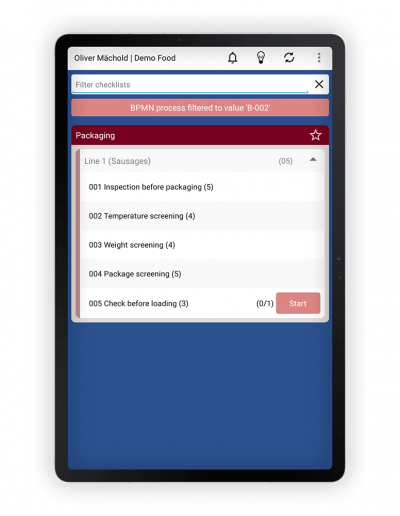

Quality checks

At defined time intervals, the tablet displays which quality checks, such as

- Temperature

- Labels (e.g. ingredients, best before date, …)

- Gas values

- Sealing

- etc.

need to be checked. need to be checked. If requirements are not met (e.g. temperature too low/too high), a deviation is automatically logged and assigned to the QM department. The QM department is then responsible for defining a corrective action.

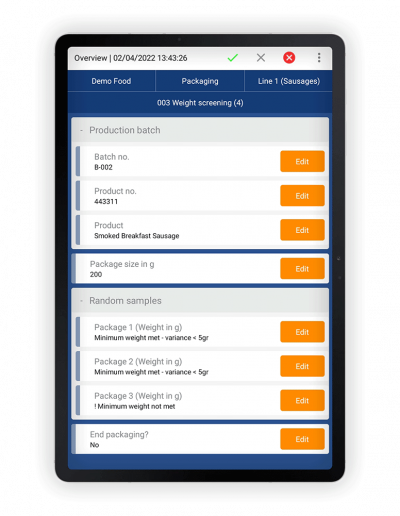

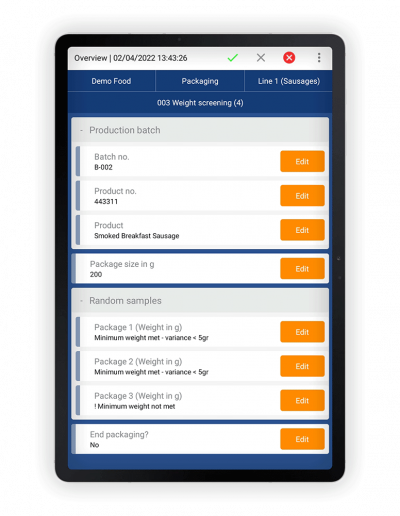

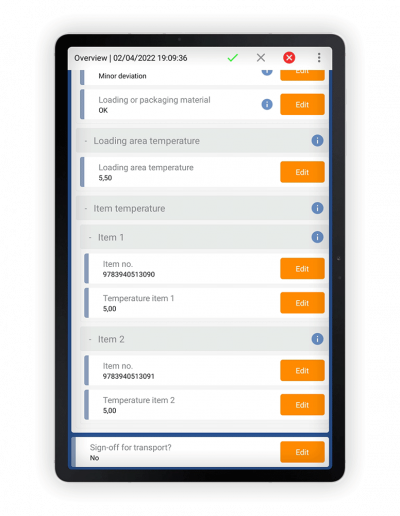

Production checks

Parallel to the QM checks, the product checks to be performed are displayed on the mobile device for execution. These refer to product specifications such as

- Weight per unit

- Weight before and after a processing step

- Raw material used

- Cooking and cooking times

- Product components (batter, breading, etc.)

- etc.

If a product component does not meet the specification (e.g. breading only 2% of the total weight and therefore too low), then a deviation is logged and assigned to the production/shift management. It is then up to the production/shift management to define a corrective action.

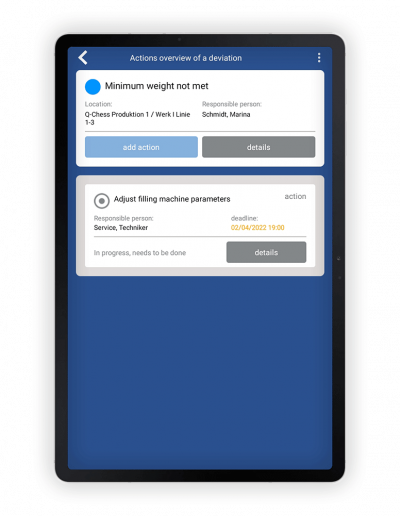

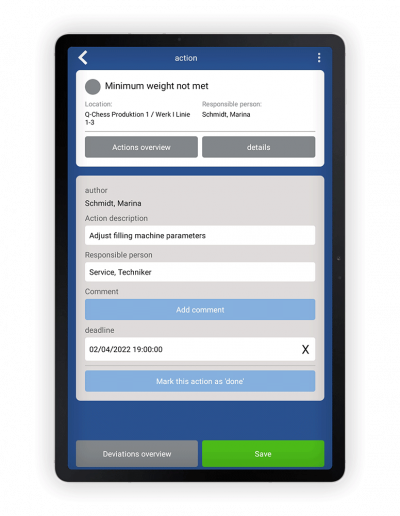

Automated deviation processing

If a treshold is exceeded during a production control or a quality characteristic is not fulfilled during a quality control, a deviation is automatically created and assigned to the production management or the QM management. Production management and quality management are notified of this on their mobile devices. It is now the responsibility of the production management or the quality management to

- Define a corrective action for the deviation

- to commission the implementation of the measure and

- verify the effectiveness of the measure.

If the action is classified as effective, then the deviation is resolved. If not, then a corrective action must be defined. The complete process of deviation processing can be carried out either on the mobile devices or with the Q-Chess Mobile Desktop App on a PC workstation.

QM inspection

If during one of the inspections the specifications were not met and a deviation was documented, then it is up to QM to decide whether the goods must be blocked or not. The QM receives an indication on the mobile device that a decision needs to be made. If QM initiates the blocking via Q-Chess Mobile, then Q-Chess Mobile calls an interface of the ERP system so that the goods are blocked there as well.

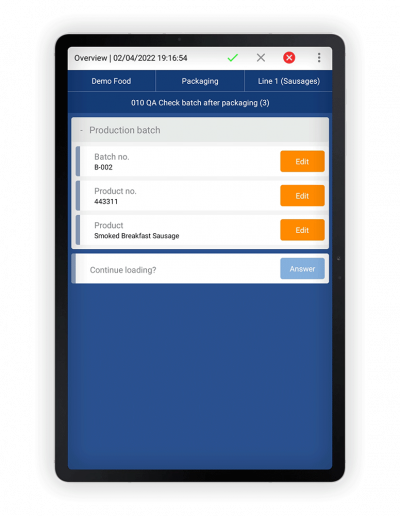

Final approval by QM

When the production of a batch finishes Quality Management must approve. For this purpose, the QM employees are shown on the mobile device that a final inspection is necessary. With a simple checklist in Q-Chess Mobile, the condition of the batch is checked and it is blocked or released for further transport.

Conclusion

With Q-Chess Mobile, a workflow can be defined quickly and easily that maps the necessary checks in parallel with the production process and displays the checks to be performed for this purpose on the mobile devices and documents them by means of data acquisition.

Here, the captured data can be evaluated in Q-Chess Mobile and certain follow-up actions can be triggered automatically.

This makes monitoring critical product parameters and quality criteria child’s play.